Road marking machines, also known as road line marking machines or pavement marking equipment, are mechanical devices specifically designed to spray paint, thermoplastic materials, or two-component materials onto roads, parking lots, sports fields, and industrial areas to create traffic lines, symbols, and safety markings. With the continuous development of transportation infrastructure, road marking machines play a crucial role in enhancing road safety, optimizing traffic flow, and improving nighttime visibility.

Types and Characteristics of Road Marking Machines

Road marking machines can be categorized into various types based on power source, construction material, and operating mode, each suited for different project requirements.

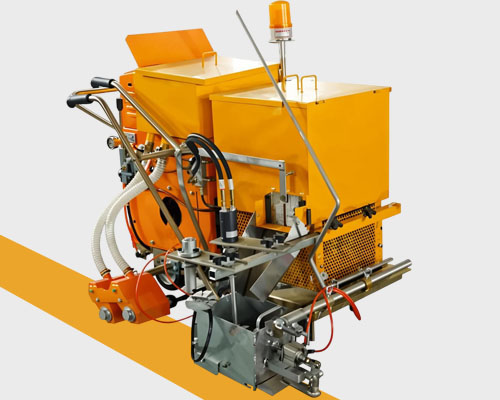

1. Thermoplastic Road Marking Machine

Thermoplastic marking machines melt solid thermoplastic coatings via a heating system (typically controlled between 180°C and 220°C), then apply the material to the pavement through scraping, spraying, or extrusion. This equipment is widely used in high-traffic areas due to its superior durability and retroreflective properties.

- Applications: Highways, urban main roads, crosswalks, airport runways, and other locations requiring long-term durability and high reflectivity.

- Key Features: Built-in heating tank, automatic retroreflective glass bead spreading system, supports rapid application and immediate traffic release.

2.Cold Paint Road Marking Machine

Cold paint road marking machines operate at ambient temperatures, directly spraying water-based or solvent-based road marking paint without heating. The equipment achieves rapid, uniform line application via high-pressure pumps and nozzles, with short drying times, making it suitable for small to medium-sized projects.

- Suitability Scenarios: Urban roads, parking lots, warehouse floors, playgrounds, and temporary line marking applications.

- Key Features: Equipped with high-pressure pumps, paint tanks, and spray guns; adjustable line width and thickness; simple operation.

3.Two-Component Road Marking Paint Machine

This machine uses two independent components (e.g., epoxy resin or polyurethane) that undergo chemical reaction and curing during application via static mixing or dynamic spraying technology. Markings exhibit exceptional abrasion resistance, weather resistance, and chemical corrosion resistance.

- Suitable Scenarios: Highways, bike lanes, industrial sites, roundabouts, and other areas demanding exceptional durability and visibility.

- Key Features: Dual-component coating delivery system, automatic mixing device, significantly extended marking lifespan post-application.

4.Vehicle-Mounted Road Marking Machines

Vehicle-mounted road marking machines are large-scale, high-efficiency equipment typically installed on trucks or specialized engineering vehicles. They are suitable for large-scale, continuous marking projects. These machines can be configured for thermoplastic, cold paint, or two-component application modes as required.

- Suitable Scenarios: Long-distance highways, international airport runways, provincial-level and above roads, and other large-scale infrastructure projects.

- Key Features: High-capacity paint tanks, integrated control and navigation systems, automated bead spreading systems, delivering exceptional construction efficiency.

How to Choose the Right Road Marking Machine

Selecting the appropriate road marking machine is crucial for ensuring construction quality and efficiency. Below are key factors to consider during your purchase:

Project Scale and Construction Frequency

For small-scale projects like parking lots or residential roads, push-type or compact self-propelled machines offer economical and practical solutions. For highways or urban thoroughfares, vehicle-mounted or large self-propelled equipment is recommended to boost efficiency and reduce labor costs.

Marking Material and Compatibility

Select equipment based on project requirements: thermoplastic marking machines for hot-melt applications, cold paint machines for ambient-temperature work, and two-component systems for ultra-high durability needs.

Durability and Operating Environment

Prioritize hot-melt or two-component machines in high-traffic areas, dense vehicle zones, or harsh climates to ensure long-term clarity and reflectivity.

Retroreflectivity and Nighttime Visibility

For projects with stringent nighttime traffic safety requirements, select thermoplastic marking machines or two-component systems equipped with glass bead spreading systems to achieve optimal retroreflective performance.

Budget and Maintenance Costs

While meeting project requirements, comprehensively evaluate equipment pricing, consumable costs, and ongoing maintenance expenses to select the most cost-effective road marking machine model.

Beyond traditional road traffic applications, road marking machines are widely used in the following scenarios:

- Industrial Safety Markings: Defining safety zones, access routes, and loading/unloading points within factories, warehouses, and logistics centers.

- Sports Facilities & Public Spaces: Area demarcation and directional markings for athletic fields, schools, and hospitals.

- Special Environment Construction: Applications like reflective markings in tunnels or anti-slip markings in humid regions require specialized road marking paint and equipment.

Furthermore, with the advancement of Intelligent Transportation Systems (ITS), road marking machines are integrating data collection and positioning technologies. This enables precise recording of marking locations and visual management of the construction process, supporting smart city development.

As vital equipment in modern traffic engineering, road marking machines come in diverse types with varying functions. Selecting the appropriate machine not only enhances construction efficiency and marking quality but also significantly extends the lifespan of road markings, ensuring driving safety. For more information on road marking equipment or construction solutions, feel free to contact us anytime!