Tag: road marking paint

-

Why White Road Marking Paint Turns Yellow After Application

Yellowing of white road marking paint is a multifaceted issue influenced by material quality, application methods, and environmental factors. Selecting high-quality thermoplastic road marking paint and utilizing precision road marking equipment can effectively prevent yellowing. Understanding its causes aids in choosing superior products and improving road marking application techniques.

-

Key Differences and Selection Between Thermoplastic and Cold Spray Road Marking Paints

Understand the distinctions between thermoplastic and cold spray road marking paints to select the appropriate solution for your project.

-

Types of Road Markings and Common Road Marking Materials

Road markings—also known as pavement markings—refer to the lines, symbols, arrows, and characters applied to roads, parking lots, and industrial floors to guide traffic and ensure safety.

-

Causes and Prevention Guide for Thermoplastic Melting Kettle Bottom Leakage

Learn the common causes of bottom leakage in thermoplastic melting kettles and discover effective maintenance methods to extend equipment lifespan. Henan Huayuan Traffic Technology Co., Ltd. shares professional tips to improve road marking paint application efficiency and ensure safer, smoother construction operations.

-

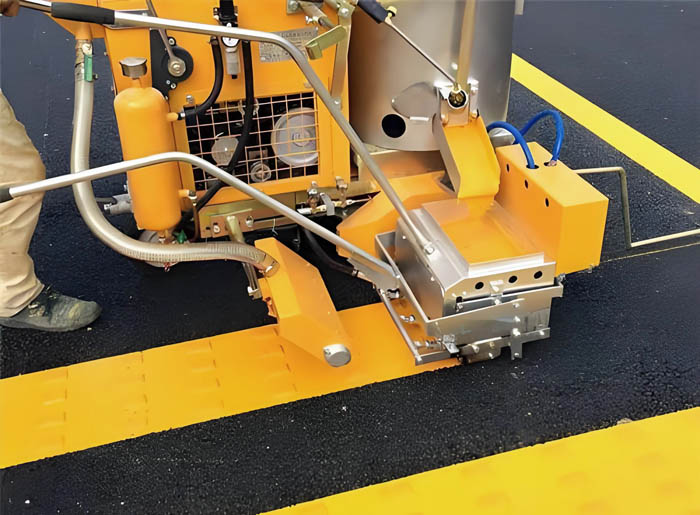

Key Points to Consider During Road Marking Machine Operation

Road marking machines come in many types, and the construction methods vary. To achieve excellent marking results, operators must follow proper procedures and understand the technical requirements of road marking construction.

-

Types, Applications, and Advantages of Road Marking Paint

What is road marking paint? Learn about their properties, applications, drying times, and how to choose the best paint to enhance road safety and visibility.

-

Key Considerations During Road Marking Machine Construction

Road marking machines come in various types, each employing distinct construction methods. To achieve high-quality results, thorough preparation and proper operation are essential. Below are several critical factors to consider during road marking construction.

-

Why Thermoplastic Road Marking Paint Softens

Understand the reasons why thermoplastic road marking paint softens in summer, and provide comprehensive solutions ranging from paint formulation and construction techniques to environmental factors. Use Huayuan’s high-quality thermoplastic road paint to improve the performance of your road markings.

-

Road Marking Machine Standards: How to Ensure High-Quality Pavement Markings

This guide provides an in-depth overview of the construction standards and operating procedures for road marking machines, including pavement preparation, marking accuracy, and coating application techniques.

-

Thermoplastic Powder Road Coating Paint, Road Marking Paint Manufacturer

Thermoplastic road marking paint is a new type of high performance road marking coating, which is characterized by wear-resistant, strong adhesion and good reflectivity. Due to the glass beads mixed in the coating, the marking paint has strong reflectivity at night, which can reduce the occurrence of traffic accidents.