In the field of road marking, choosing the right road marking machine is crucial to ensure road safety and improve traffic efficiency. Cold paint road marking machines and thermoplastic road marking machines are two common types of equipment, each with their own advantages and disadvantages, suitable for different scenarios and needs. Below we will compare and analyze these two types of road marking machines in terms of durability, application temperature, surface compatibility, drying time, cost and more to help you make the best choice for your project.

Durability: Thermoplastic is better

Thermoplastic road marking is known for its superior durability. Through the hot-melt application process, thermoplastic materials are able to form highly abrasion- and weather-resistant road markings that last far longer than cold-painted markings. Particularly in high traffic areas, thermoplastic markings can withstand frequent vehicle traffic and remain visible. Therefore, thermoplastic road marking machines are the better choice for projects that require long-term road marking clarity.

Application temperature: cold paint is more flexible

Cold paint road marking machines offer more flexibility when it comes to application temperatures. Cold paint materials can be applied at ambient temperatures without the need for heat, making it possible to work in a wider range of weather conditions. In contrast, thermoplastic materials need to be heated to a molten state prior to application, which increases the difficulty and cost of construction. As a result, cold paint road marking machines may be more suitable in areas where temperatures are cooler or weather is more variable.

Surface compatibility: Cold paint is more versatile

Cold paint road marking machines also excel in surface compatibility. It is suitable for a wide range of road surfaces, including asphalt, concrete and even brick. This makes cold paint road markers more versatile for smaller projects or in areas with limited resources. Thermoplastic materials, on the other hand, are better suited for asphalt surfaces and may require additional treatment or adjustments for other types of road surfaces.

Drying Time: Cold Paint is Faster

Cold paint road marking machines have a clear advantage when it comes to drying time. Cold paint materials dry quickly, allowing for faster project completion and less traffic disruption. This is especially important for emergency projects where traffic needs to be restored quickly. Thermoplastic materials, on the other hand, require a much longer cooling time to form a hard road marking, which adds to the cycle time and cost of construction.

Cost: A Comprehensive Consideration

When it comes to cost, cold paint road marking machines have relatively low initial investment and operating costs. Equipment and materials are more affordable, making cold paint marking machines ideal for projects with limited budgets. However, it is important to note that while cold paint markers are less costly, they may not last as long as thermoplastic markers and require more frequent reapplication. As a result, thermoplastic road markers may be more economical for long-term projects.

RECOMMENDATION: If you are using thermoplastic road marking paint, we recommend purchasing a preheater in addition to a thermoplastic road marking machine. Preheaters are used in conjunction with thermoplastic road marking paint machines to melt the thermoplastic paint, saving fuel energy and heating time, and increasing construction efficiency.

When to choose a cold paint road marking machine?

Short-term marking: for temporary or low-traffic areas where a quick and cost-effective solution is needed.

Various Surfaces: When working on different types of roads such as concrete and asphalt.

Quick turnaround projects: where fast application and drying times are critical.

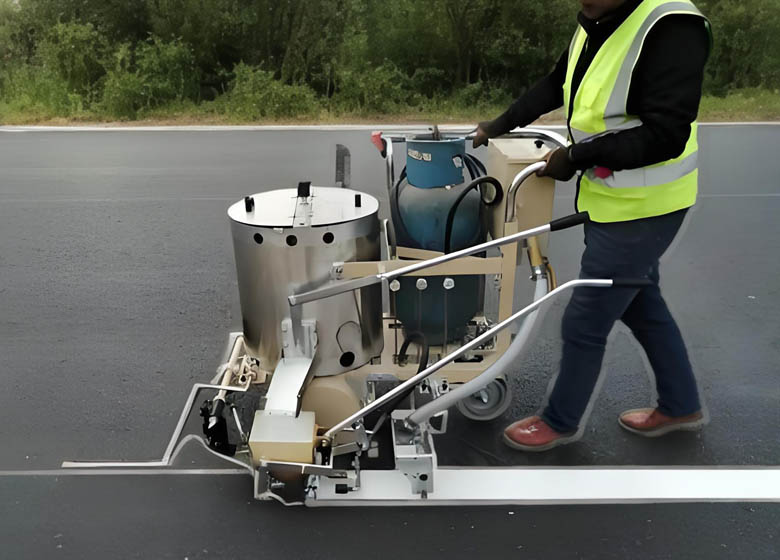

When to choose a thermoplastic road marking machine?

Heavily trafficked areas: for roads with heavy vehicular traffic and where durable markings are required.

High durability required: where maximum abrasion resistance is sought.

Professional appearance: for projects requiring a high quality, smooth surface.

Putting it all together: choosing the best road marking machine for you

When choosing between a cold paint road marking machine or a thermoplastic road marking machine, you need to consider the specific needs and requirements of your project. If longevity and visibility are primary considerations, then a thermoplastic road marking machine may be the best choice. However, if cost-effectiveness and versatility are more important, a cold paint road marking machine may be better suited to your project. By understanding the differences between the two and incorporating your practical needs, you can choose the most appropriate equipment for your road marking project, ensuring that the road markings are long-lasting and meet safety standards.