The coating can be applied to a variety of road marking machine, 1-3 minutes after spraying can be dry and open to traffic, and can even be constructed without obstructing traffic. Thermoplastic coating film has complete and clear lines, sharp edges and corners, high vividness and strong three-dimensional sense. The use of thermoplastic road marking paint can effectively improve the service life of road marking, enhance the visibility of road marking in rainy days and at night, to ensure driving safety.

Specification:

| Product Name | Thermoplastic Road Making Paint |

| Usage | Road Marking Paint |

| film appearance | No wrinkle, spot, blister, crack, off, Glued tyres, the color of fill appearance should be closed to standard |

| alkali resistance | There’s no abnormal phenomena 24 hours after being Soaked in the Saturated calcium chloride solution |

| The coating crack resistance at low temperature | Keep 4h in ten degrees below zero, then keep 4h in indoor temperature. After repeating three times, there’s no crack |

| thermal stability | Keep 4h in between 200°C to 220°C when stiring ,there’s no obvious phenomenon of yellowing, coking, caking etc. |

| water resistance | There’s no abnormal phenomena 24 hours after being Soaked in the water |

Features of thermoplastic road marking paint:

- Fast drying – Cures in 3 minutes, much faster than solvent-based coatings.

- High durability — thick coatings (up to 2 mm) ensure long-lasting performance (up to 24 months on highways).

- Excellent nighttime visibility — contains reflective glass beads to enhance nighttime reflectivity.

- Cost-effective — lower material costs compared to other road marking solutions.

Suggested applications for road marking paint

Thermoplastic road marking paint is suitable for the center line, lane demarcation line, pedestrian crossings, intersections, parking lots, and highways without lighting at night; the adhesion of asphalt pavement is the best, followed by cement pavement; it is not suitable for sandy pavement, brick pavement, temporary pavement, and pavement intended to be expanded within half a year.

During construction, the coating needs to be heated to 180°C – 220°C using thermoplastic melting kettle (the specific temperature needs to be determined according to the type of petroleum resin in the coating and the formula), so that the thermoplastic resin is melted and the coating presents a molten flow state. Subsequently, it is applied to the road surface using a special road marking machine, and can be cured at room temperature. When coated on concrete pavement, the adhesion may be poor due to the mechanical tooth cooperation between the high temperature molten coating and the concrete pavement. Therefore, it is necessary to pre-coat road marking paint to enhance the adhesion between the road surface and the paint.

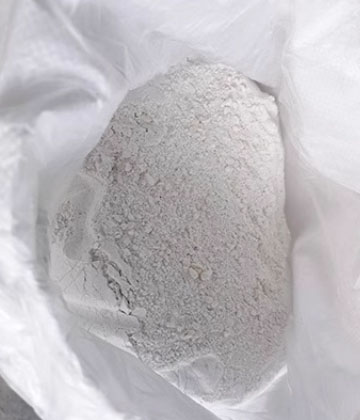

Our thermoplastic road marking paint adopts the best mineral resources in China’s production area and has the best whiteness in China. Reasonable particle size distribution, low oil absorption, better combination with C5 petroleum resin, high compressive strength, good fluidity and excellent anti-settling performance of coating.

Huayuan’s advanced road marking paint is your reliable choice for excellent road safety solutions. Contact us now to get the best road marking products for your needs!